LEMUR technology

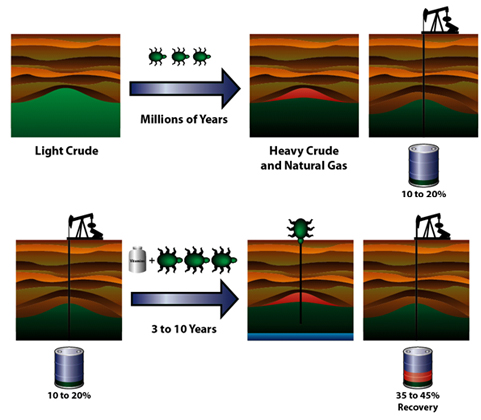

Profero’s technology produces methane in the reservoir by accelerating the naturally occurring process of methanogenesis. This involves bacteria and archea already present in the reservoir biodegrading constituent parts of crude oil into natural gas and residual heavier oil. The resultant methane created can be produced or retained in the reservoir to increase pressure provoking greater oil production and recovery.

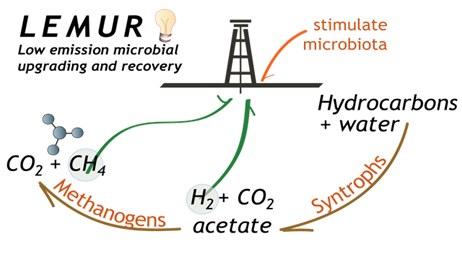

Profero scientists are world experts on the biodegradation of oil as it occurs naturally. Their breakthroughs in understanding natural methane production reactions form the basis of Profero’s LEMUR™ (Low Emission Microbial Upgrading and Recovery) technology. The premise behind the LEMUR™ technology is to harness and develop the natural biodegradation process by removing rate-limiting conditions and accelerating hydrocarbon biodegradation.

The following diagram illustrates the natural process and represents the framework for how Profero seeks to control the biodegradation acceleration.

Methanogenesis acceleration has been aspired to by the oil industry for some time but to be commercially significant then the acceleration must be sufficient to provoke methane generation of the scale necessary for generation of sustained oil and/or gas production at attractive rates. Each oil reservoir differs but the deep understanding of the biological processes in the pertinent ecosystems has allowed the development of a patented process of methanogenesis acceleration believed to be capable of the scale necessary for commercial application in many oil reservoirs.

The central process has enabled Profero to develop critical applications for commercial activity including:

- Oil and aqueous geochemical, microbiological and reservoir simulation tools that incorporate biological reaction systems

- Use of the above tools to identify appropriate oilfields that have active microbial populations carrying out the natural process at the correct stage for intervention

- Targeting of the appropriate reaction zones

- Injection of nutrient-containing waters that will accelerate the natural microbial process

- Advanced, optimized, controllable, recovery processes

The process does not require specialist engineering equipment but utilizes standard injection and production wells and related infrastructure. This can include existing wells including abandoned wells although for optimal results a new well configuration may be advisable.